Chemical-Resistant Machinery Sealing Strip - Acid/Alkali Proof for Chemical Plant Equipment

- group name

- Machinery Sealing Strip

- Min Order

- 100 meter

- brand name

- RESRUB rubber and plastic products manufacturer

- model

- NO.G20240118007

- Nearest port for product export

- Shenzhen, Guangzhou

- Delivery clauses under the trade mode

- FOB, CIF, EXW, FAS, FCA, DDP, Express Delivery

- Acceptable payment methods

- T/T, L/C, D/P D/A, MoneyGram, Credit Card, PayPal, Westem Union, Cash

- update time

- Thu, 26 Feb 2026 21:51:05 GMT

Paramtents

Color (General) Custom

Material EPDM

Length Custom

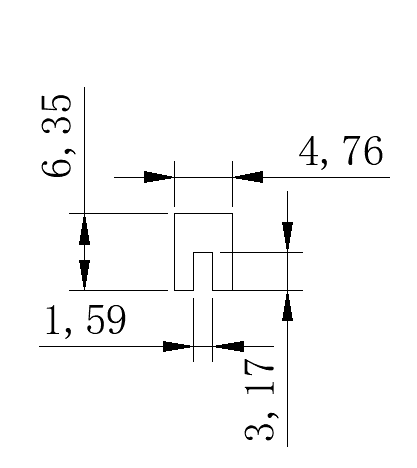

Dimension Custom

Temperature Range -45°C—125°C

Shore Hardness 50-95 Shore A or customize

Tensile strength 5~12Mpa

Elongation at break 400%

Packging & Delivery

- 48cm x48cm x32cm

-

Min Order100 meter

Briefing

Our Machinery Sealing Strip is an essential component designed to optimize the performance and lifespan of industrial machinery.

Detailed

Machinery Sealing Strip Introduction

This sealing strip effectively blocks dust, debris, moisture, and other contaminants, preventing them from infiltrating the machinery's internal components. By doing so, it helps to reduce wear and tear, minimize the risk of mechanical failures, and improve overall operational efficiency.

Customization Options

RESRUB could produce the tubing with enough length to fully connect any size loop.

And available to custom colors, such as black, white, pink, etc.

Material Advantages

Constructed from high - quality rubber or silicone materials, it offers remarkable flexibility and durability, enabling it to withstand the rigors of continuous operation in demanding industrial environments.

Machinery Sealing Strip Properties:

| Length | Customizable | OEM/ODM | Available |

| Logo | Customer Logo Available | Lead Time | 10 Days |

| MOQ | 100 Meters | Application | Machinery & AutomationEquipment |

Installation matters

When installing a mechanical seal, check whether the seal has any defects, clean the installation surface, and ensure that it is suitable for the mechanical installation. Perform the installation correctly according to the type, and carefully check the function and appearance after installation.

What are the main functions of a machinery sealing strip?

A machinery sealing strip primarily serves to prevent leakage. In fluid - or gas - handling machinery, it stops the escape of liquids like oil, coolant, or hydraulic fluid, and gases such as compressed air or steam. This not only conserves resources but also ensures the proper functioning of the machinery.

How do I select the right machinery sealing strip for my equipment?

First, consider the operating conditions of your machinery. If it operates under high pressure, you need a sealing strip with high - pressure resistance. For high - temperature applications, choose a strip made of heat - resistant materials like silicone or certain types of rubber. The nature of the substances being sealed matters too

How often should I replace the machinery sealing strip?

The replacement frequency depends on several factors. If the machinery operates in harsh conditions, such as high temperatures, high pressures, or in contact with corrosive substances, the strip may need to be replaced more frequently, perhaps every few months to a year.

Item | Machinery Sealing Strip | |

Size | Customize | |

Material | EPDM | |

Hardness | 70 Shore A or customize | |

Color | Black or customize any color | |

Density | ≤1.33g/cm³ | |

Temperature resistant | -40℃~120℃ | |

Tensile strength | ≥7Mpa | |

Elongation at break | ≥400% | |

Lead time | 3 days for sample, 15 days for batch order | |

Packing method | Carton/ PE bag / Wooden pallet / Paper roll | |

Price tip | The price above is for your reference, final actual price depends on your design,material request, surface treatment, order quantity, package request, etc. | |